Is Your Intralogistics System Leaking Money?

Struggling with heavy, long materials?

Standard logistics equipment isn’t designed to handle large, heavy raw materials efficiently.

Our solutions optimize storage and retrieval, improving workflow and minimizing damage.

Facing low throughput and capacity issues?

General-purpose equipment limits your operations.

Our advanced systems increase throughput, helping your operations scale smoothly without bottlenecks, reducing costs and boosting capacity.

Frequent errors and material damage?

Handling errors causing accidents?

Human error and material mishandling can lead to costly injuries and damage.

Our automated systems reduce risks, ensuring precise material handling and protecting your workforce and goods.

Losing inventory to over-stacking?

Over-stacking materials not only wastes floor space but also risks damage.

Our vertical storage solutions maximize space efficiency and ensure your inventory stays safe and accessible.

High labor demands and inefficiency?

Processes too labor-intensive?

Automating repetitive tasks frees up your team to focus on more important work.

Our robotic solutions streamline workflows, reducing labor costs and increasing productivity.

Disorganized inventory costing you time?

Poor inventory management leads to wasted time and lost productivity.

With real-time tracking and predictive analytics, our systems provide better control over your stock, saving time and resources.

Paying for redundant handling?

Unnecessary handling increases operational costs.

Our integrated storage solutions cut down on redundant movements, optimizing your material handling process and saving money.

Poor space utilization?

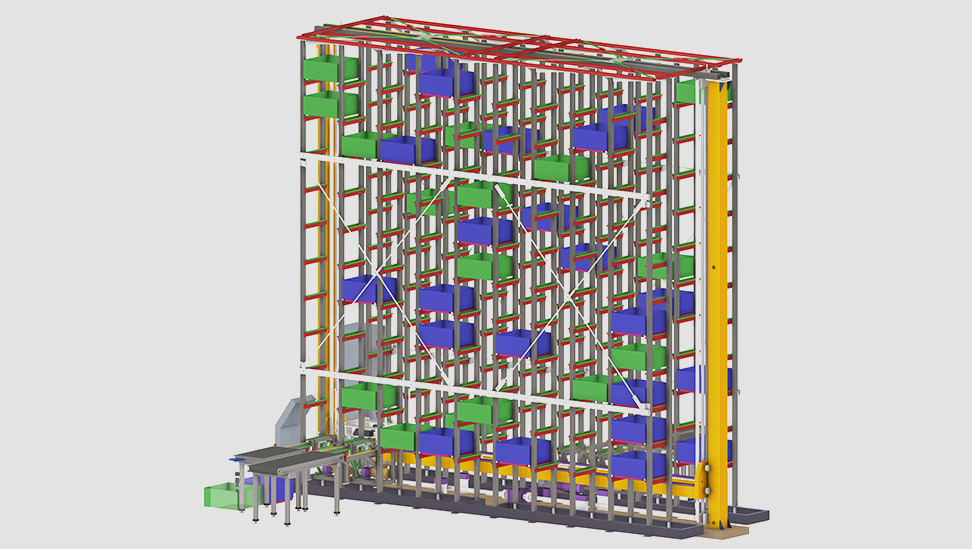

Wasting vertical space?

Unlock your shop floor’s storage potential with high-density racking and vertical storage systems.

Our solutions ensure you make the most of every inch of available space, reducing wasted floor area.

Machines waiting on materials?

Downtime hurts both efficiency and OEE.

With just-in-time delivery and automated material handling, we ensure materials are available when your production lines need them, minimizing delays.

Struggling with data visibility?

Lack of real-time data slows decision-making and reduces efficiency.

Our integrated systems provide full visibility, ensuring smooth coordination between storage and production processes.